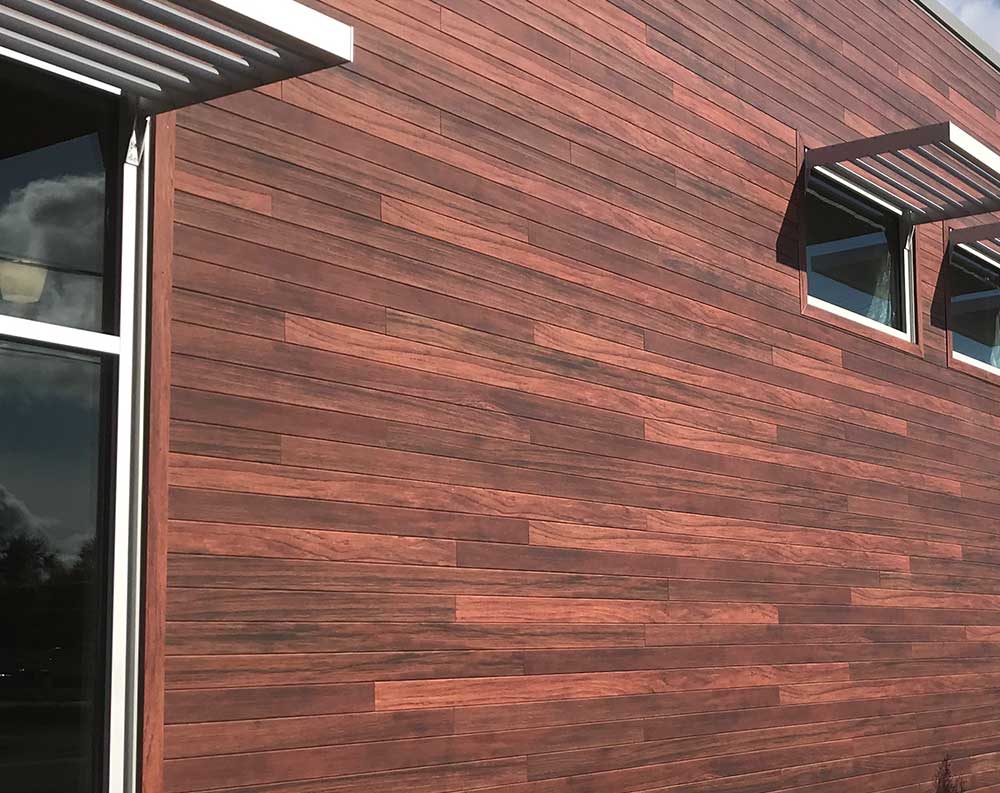

Faux Wood Siding Solutions

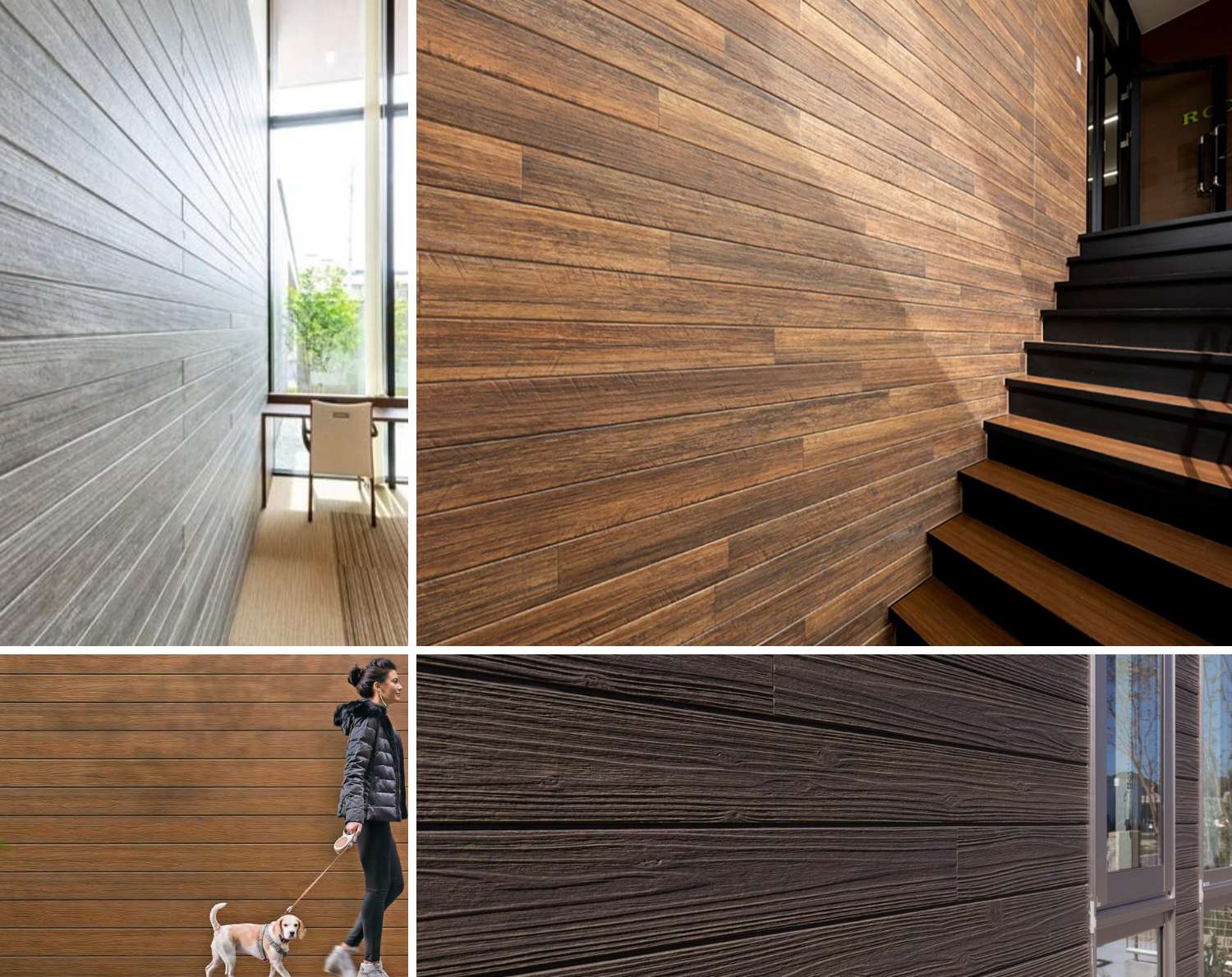

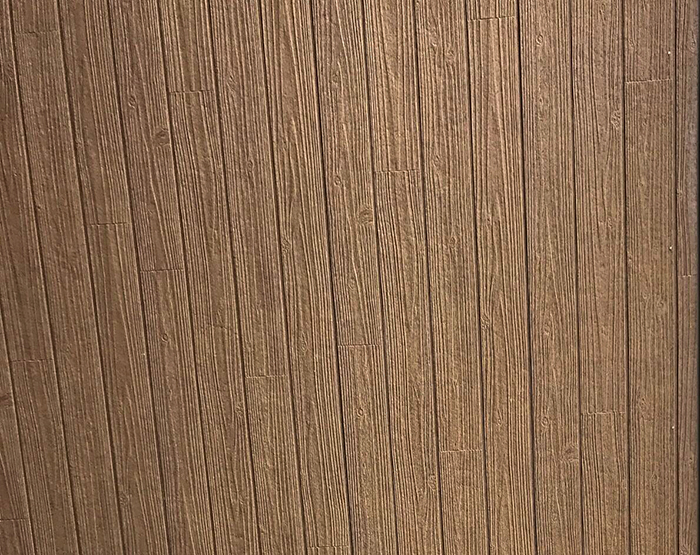

Types of Faux Wood Panels

Advances in faux wood siding offer a sustainable, durable, and beautiful alternative to wood.

Rising wood prices and concerns about ecology have contributed to a rise in demand for faux wood siding solutions. Wood siding is not a preferred option these days primarily due to its various disadvantages. The biggest drawback of wood siding is that it offers no insulation. It is prone to damage and needs weather stripping. Without regular maintenance wood can rot, warp, or twist, allowing water to seep behind the siding, potentially causing damage to the building’s structure. Also, insects will damage the wood without some regularly applied protection.

Explore the options and discover the realistic beauty of faux wood panels.