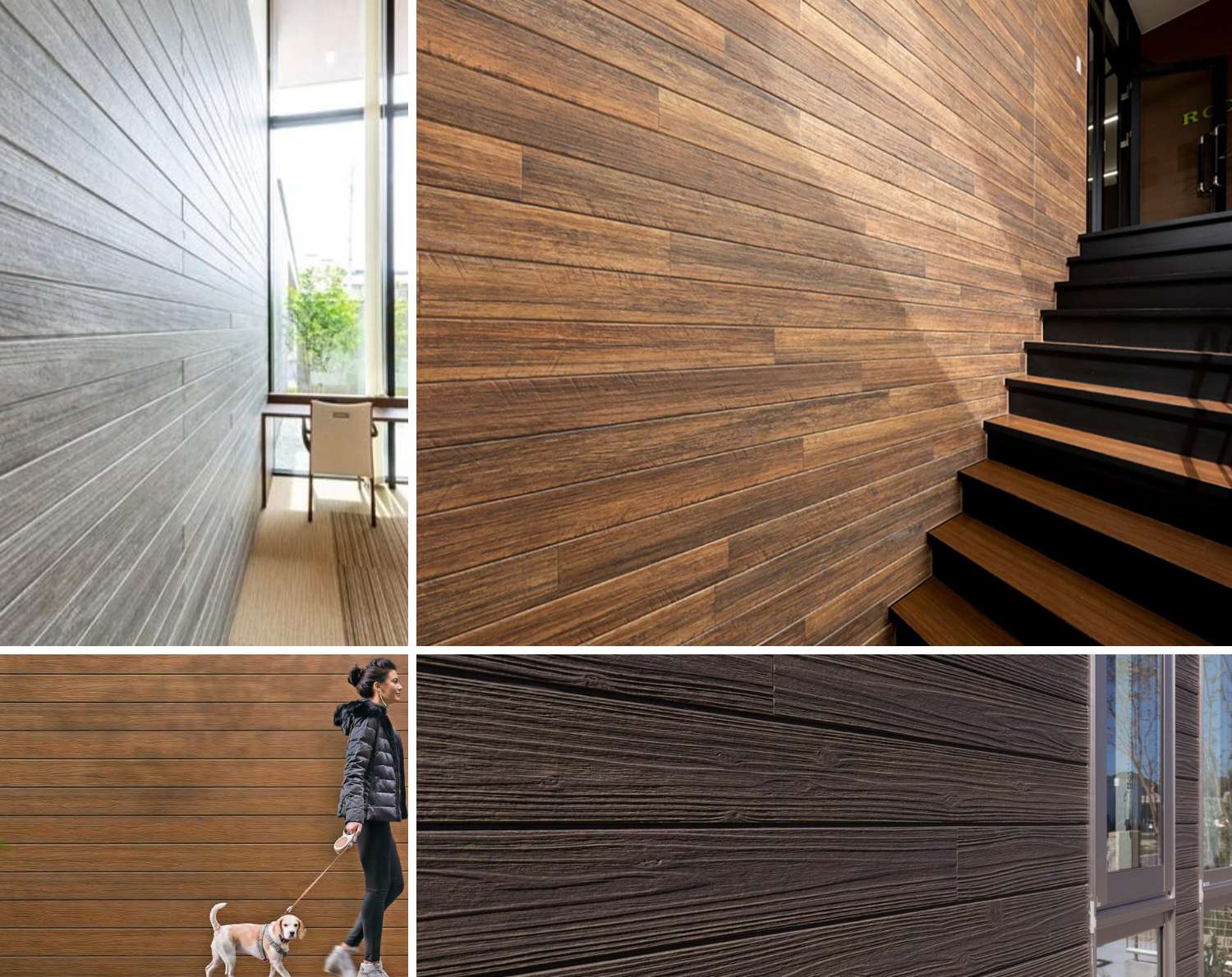

Knight Wall Systems manufactures versatile, ventilated rainscreen attachment systems that accommodate an expansive array of cladding options. Knight Wall Systems can be specified with any cladding/siding product that meets the general loading requirements of each system (typically restrictions begin at 15 PSF.)

- Efficient: Code-compliant; exceeds the requirements in each climate zone.

- Save Energy: Systems reduce long-term energy consumption and CO2 emissions.

- Save Time: Isolators come attached to brackets and/or fasteners. All fasteners required for the system assembly are supplied, including wall anchors.

- Long Lifespan: Highly corrosion resistant – Zn-Al-Mg coating lasts up to 10 times that of typical galvanizing. Solid stainless steel is also available.

- Save Money: Fewer materials required to reach code-compliant insulation levels and quick installation times deliver cost savings, both upfront and during the service life of the building envelope.

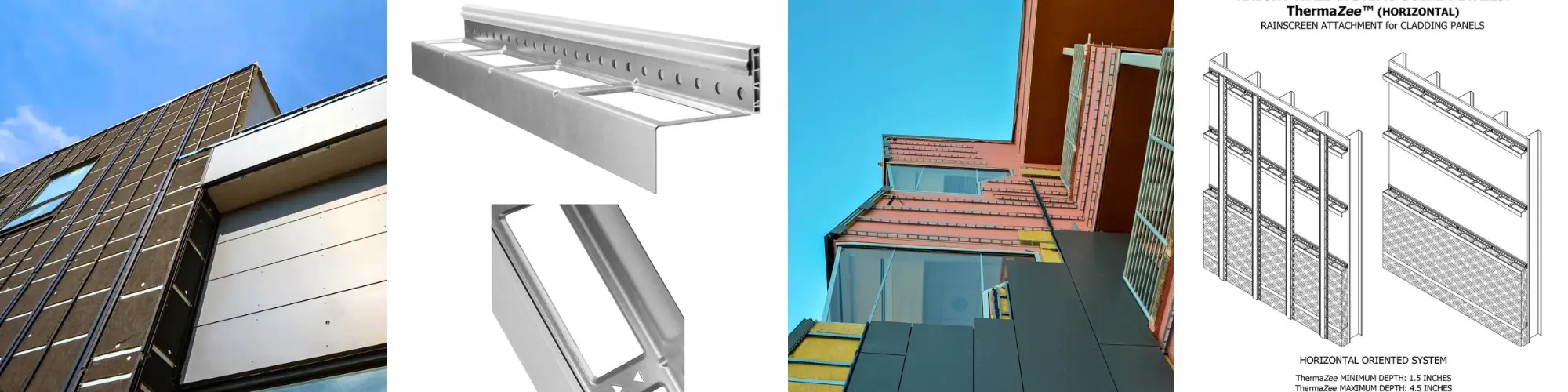

Knight ThermaZee® gives installers and designers Z-furring and code-compliant thermal performance. With reduced thermal bridging that rivals modern thermally isolated clip and rail systems, the thermally improved ThermaZee dramatically increases the rainscreen wall assembly’s performance.

The ThermaZee employs a specially designed, hollow, thermal isolation strip complimenting other performance enhancements at the web of the girt. The web’s unique punch pattern has a substantial reduction in metal penetrating the insulation – about 75% – which decreases heat flow through the girt. Additionally, the girt’s notched bends and flared punches add extra strength.

Like traditional Z-furring, the ThermaZee can be installed either vertically or horizontally, attached to a variety of substrates such as steel studs, wood studs, CMU, and concrete. Also, like traditional furring, a variety of claddings can be attached directly or with secondary rails. These include fiber cement, metal panels, HPL panels, or aluminum composite material (ACM), among others.

The CI® System uses unique ¾” deep vertical box girts – called CI-Girts™– designed to properly disburse the façade loads over exterior rigid board insulation – with only unique thermally isolated fasteners penetrating the thermal barrier thus minimizing thermal bridging. For basic, cost-effective horizontal claddings, only a single layer of CI-Girts may be needed. For more complex cladding designs or types, choose from a wide variety of Knight Wall secondary rails for those panels requiring specific attachment points.

CI® Systems components are produced in standard and custom lengths, in either 16 or 18 gauge Zinc-Aluminum-Magnesium coated steel (standard silver or black PVDF coated) and also available in stainless steel.

This easy to design and even easier to install, engineered drop-in system solution will provide any project with design versatility while still meeting or exceeding North American energy code requirements. The CI® System attachment completes the rainscreen envelope design, whether choosing metal panels, lap siding, Aluminum Composite Material (ACM) panels, terra cotta, GFRC, or many more. And choose any brand of insulation meeting minimum compressive strength and code requirements, simplifying design specifications.

Advantages of CI® System

- Outstanding thermal performance with 25 PSI Polyiso foam insulation.

- Vertical CI-Girts can be spaced 16”, 24” or 32” O.C. (every other stud.)

- No notching or cutting of exterior rigid board insulation required like with Z girts, brackets or clips.

- Easily installed over any type of substrate – steel studs, wood studs, CMU, concrete or brick.

- Limited labor material warranty.

The KWS MFI® System dramatically reduces the thermal bridging within rainscreen wall assemblies, while providing limitless design options for building facades; combining energy efficiency, façade versatility, and long-term sustainability. Being primarily comprised of steel, the MFI System offers a resilient, durable and non-combustible option to meet today’s high demand.

The MFI System uses unique thermally isolated intermittent clips – called Thermabrackets® – that can be spaced all the way up to 32” O.C. They use a unique thermal isolation assembly, called ThermaStop™, creating one of the most thermally efficient mineral fiber cladding attachment systems on the market today – typically outperforming standard metal clips and rails and even FRP brackets and rails.

The continuous rails attaching to the brackets may be oriented vertically or horizontally. Quickly plumb the facades during installation with an adjustable rail/bracket connection or use KWS unique, self-aligning, structural shims. The MFI System may be used with or without secondary rails for fiber cement, metal panels, terra cotta, phenolic panels, Aluminum Composite Material (ACM), and more.

A rail designed with performance, durability and the installer in mind.

Perforated cladding attachment rails means better drainage and ventilation for the façade. Knight Wall Systems’ PanelRail® & RevealRail™ are typically used as a second layer of rails atop the CI System, HCI System, MFI System or other types of assemblies to help accommodate different panel layouts, sizes or add depth.

The PanelRail or RevealRail may also be used in assemblies not requiring exterior insulation. In these simple assemblies the PanelRail or RevealRail can be installed directly over the substrate (steel studs with gypsum sheathing, wood studs with sheathing, CMU, structural sheathing, etc) and allow for increased ventilation behind the cladding while still allowing drainage.

Where a typical furring channel would require a hole drilled in the field for the wall anchor, pre-punched holes on the PanelRail for the wall anchors make installation simple over CMU, concrete, wood studs, and structural sheathing – saving time and cutting labor costs.